Tiny House Village for Young Women Aging Out of Foster Care Receives $1M Contribution from Author, Nora Roberts

The future prospects of young women facing the critical transition from youth care to independent adulthood just got a significant boost. San Mar Family &

Tiny House Homeless Village’s Benefits Over Conventional Homeless Shelter

In the quest to address the escalating homelessness crisis, innovative housing solutions are constantly being sought and tested. One such innovation that has garnered attention

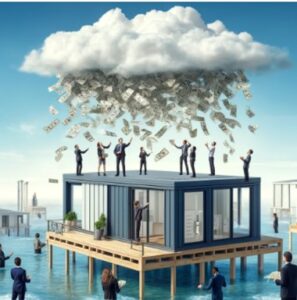

Seven Hidden Costs of Modular Construction: Keeping Your Profits on Track

Modular construction has become a popular choice for its efficiency and speed. However, even established factories can fall victim to underestimating hidden costs, leading to

Understanding VC Valuations in the Modular Housing Industry

Venture capital (VC) investment strategies and valuation methods can often seem disconnected from traditional financial metrics. This is particularly noticeable in manufacturing sectors such as

Is MMC Losing Its Allure in the UK?

Welcome to the world of Modern Methods of Construction (MMC) in England—a realm where building homes isn’t just about slapping together some prefab parts on

Revolutionizing the Future of Homebuilding Towards Eco-Friendly Construction”

The homebuilding industry finds itself at a pivotal moment. With real estate contributing a staggering 40% of global carbon emissions, it’s clear that change is

Homeless Communities: Helping Churches and Non-Profits Navigate the Bumps in the Road

In non-profit and Church community initiatives, one solution stands out for those experiencing homelessness: modular Accessory Dwelling Units (ADUs). These compact living spaces have been

What Are the Chances of a Modular Startup Succeeding Without an Experienced “Startup Consultant”?

Lately, I’ve been reading about people and groups, both humanitarian and for-profit, announcing they are going to start a new modular home factory. They all

Modular Hospitality Construction: The “Good” and the “Not So Good” for a Modular Factory

Beneath the advantages for a modular factory to build large projects rather than single and multifamily projects of less than 40 modules, lies a world

Finding Production Managers: A Timely Discussion

by Gary Fleisher, the Modcoach Recently I talked with Bill Murray, one of offsite construction’s most seasoned consultants with over 40 years of modular industry

Revolutionizing Talent Acquisition in Offsite Construction – Part Two

By Gary Fleisher, the Modcoach The demand for niche skills and specialized talents in offsite construction is skyrocketing. As our industry continues to expand, companies

Pioneering Skills for the Future: The Rise of Niche Talents in Offsite Construction – Part One

By Gary Fleisher, the Modcoach The offsite construction industry is currently experiencing a significant transformation, propelled by the global shift toward more efficient, sustainable, and

Mastering Equilibrium in Modular Home Manufacturing

Recently I toured a modular home factory on the East Coast that was as close to optimal as I’ve ever seen. When I mentioned this

A 6-Step Comprehensive Guide to Rescuing a Failing Modular Construction Factory

By Gary Fleisher, the Modcoach Modular construction is revolutionizing the way buildings come to life, promising significant gains in efficiency, sustainability, and cost-effectiveness. Despite these

Innovative Construction Group Announces Major Expansion in North Carolina

In a significant boost to the local economy, PulteGroup’s Innovative Construction Group (ICG) has announced plans to invest $40 million in establishing a new manufacturing

8 Often Overlooked Signs That Your Modular Home Factory Idea Might Be Flawed

When it comes to starting a business in the modular home industry, enthusiasm and entrepreneurial spirit are essential, but they are not sufficient on their

The Overlooked Factors in Modular Home Factory Investments

Risks Investors Can’t Afford to Ignore Investors flock to new modular home factories, enticed by the promise of high returns and a booming housing market.

The Potential of Modular Cabins

In the picturesque town of Atglen, Pennsylvania, a family-owned business, Zook Cabins, is reshaping the landscape of modular housing. This innovative company has recently earned

Pioneering Affordable Housing with Modular Brands of Chattanooga

In the heart of Chattanooga, Tennessee, an established factory is building affordable housing. Modular Brands, under the visionary leadership of Harrison Langley—a seasoned entrepreneur with

Innovative Solutions in Compact Living: Addressing Affordable Housing and Homelessness

As today’s housing prices continue to soar, innovative living solutions like tiny houses, auxiliary dwelling units (ADUs), and park model RVs are emerging as vital

The Tumultuous Tides of Modular Construction: Layoffs, Lawsuits, and Lack of Experience

2024 was earmarked as a pivotal year for the modular and offsite construction industries—a forecasted turnaround from the sluggish pace that had characterized previous periods.

Day Four: Making New and Visiting Old Connections in New England

On the fourth day of my New England road trip, I immersed myself in the innovative construction technology world at Logic Building Systems in Brattleboro,

Day Three: Discovering Innovation and Craftsmanship in New England

On the third day of my exploration through New England, I was privileged to visit two remarkable places that epitomize innovation and craftsmanship: a modular

Day Two: Insights from Local Offsite Retail Builders

In the heart of New England, the housing market is bustling with a blend of modular and manufactured homes. Over the past two days, I’ve

Day One: A Fresh Perspective from the Forefront of Modular Construction

As I embark on my road trip through the Mid-Atlantic and New England regions, I am set to explore the thriving world of modular construction.

Warning Signs: Is Your Modular Home Supplier in Financial Trouble?

The financial well-being of a modular manufacturing plant is pivotal. It affects not just the company itself but also the suppliers, customers, and investors tied